PICK TO LIGHT system supporting the flow of goods from the production line to the shipping warehouse

For one of our clients from the Automotive industry, we have developed and implemented our own original traffic light system for signalling when completed packaging containers are ready to be collected, for products packed straight from the production line.

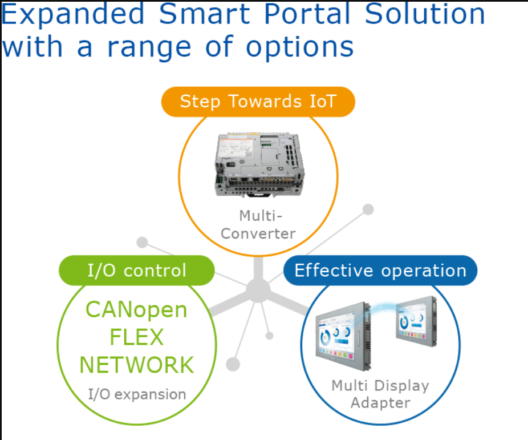

The system, in addition to giving a direct signal when packaging containers are completed, allows for recording and real-time display of statistics related to the rotation of packaging containers at each of the defined work stations. Access to current and historical data is possible in person at the production line and online via an internet browser. We obtained all of the functionality through innovative use of the HMI ProFace SP 5000 series equipped with the Smart Portal interface, allowing for data from the production equipment to be integrated with office applications, without the need for developing and implementing a specific application for processing and visualising the data.

The traffic light system is based on the principle of transferring visual information between the area for packing components and the area for collection of completed containers. The visual information is based on the signalling of a change in the status of the box into which individual products from the assembly line are packed, via a light of a certain colour. On the side of the operators completing the containers for components, there are boxes installed with a button for changing the container status light (in the packing process/ready for collection). After completing the products in the container, the operator presses the appropriate button, changing the colour of the light in the area for collection of completed containers, i.e. on the side of the receiving operator. The packing operator’s box is equipped with a button and two lights signalling the following statuses: 1. “in the packing process” (green) / 2. “ready for collection” (red). After the normal waiting time for a completed container has been exceeded, the light starts flashing, thus indicating the place with the highest priority for collection.

The operator collecting the container acknowledges collection by pressing the button on his/her side, which causes the light to change again to green on both sides. The green light is maintained until the status changes again after a container has been completed by the packing operator. The change of status is performed via a controller, programmed to allow for correct operation of the system and for visualising the status of individual stations on LED television screens.