The production of new machinery and equipment is currently the most important and the broadest area of activity of Apena-Remont Sp. z o.o. In cooperation with our clients, we develop a concept of a machine or a piece of equipment, create a design, prepare full technical documentation and installation diagrams and design the control and safety systems.

As part of the comprehensive implementation process, we also manufacture all parts and subassemblies of the machine, select and purchase the necessary commercial components, assemble the mechanical parts and installations as well as program the PLCs and operator panels. After commissioning the machine, we carry out testing and prepare additional documentation with details of the machine operation as well as all instructions and technical files required for the CE marking and the EU declaration of conformity.

A new machine or a piece of equipment built by our company is delivered to the ordering party and commissioned on the premises with the support of our specialists. We ensure an efficient, quick and comprehensive process which includes starting the machine, verifying the operating parameters and providing training to the client’s staff. All our machines and equipment are subject to a warranty and we ensure a quick response to reported issues.

Our construction and technological facilities with experienced staff, computer equipment and computer-aided design software such as AutoCAD, Solid Edge and Sprute CAM allow us to create new, optimal technical solutions. We develop applications with a high level of automation, which use industrial robots and manipulators, at the same time ensuring the appropriate level of safety systems. Our new products are safe, efficient and technologically advanced, and the applied technical solutions and good quality commercial components ensure a long lifespan for our machines and equipment with low maintenance and inspection expenditure.

We are looking forward to doing business with you!

At present, we have a team of over 100 employees

with secondary and higher technical education and qualifications confirmed by courses and state certificates, as well as professional experience proven by their performance.

Dwustanowiskowy automat spawalniczy ze stołem obrotowym BCW I

Czterostanowiskowa maszyna do seryjnego przewężania rur MPR I-4

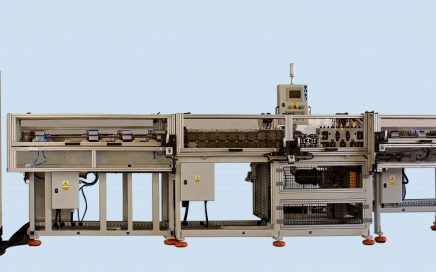

Linia do szlifowania pierścieni łożysk

Czterostanowiskowa maszyna do seryjnego przewężania rur MPR II-4

Spawarka układu paliwowego

Maszyna do mycia tłoków – widok ogólny

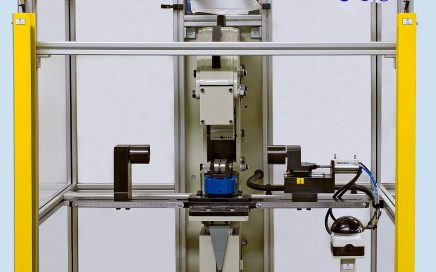

Pionowa kalibrownica rur PKR

Maszyna do mycia korpusów amortyzatorów

Stanowisko do identyfikacji stref hartowania

Dwustanowiskowy poziomy automat spawalniczy Esmeralda

Myjka potokowa ze stołem odkładczym i selekcją tłoczysk

Układ transportowy do maszyny Big Bag

Dwustanowiskowy automat do spawania liniowego ASLd (Hook Welder)

Maszyna do szczotkowania gwintów tłoczysk SGT

Walcarka do rur o profilu prostokątnym

Dwustanowiskowy automat spawalniczy ze stołem obrotowym BCW II

Dwupalnikowy automat spawalniczy DAS

Maszyna do mechanicznego znakowania rur

Automat Spawalniczy Dwustanowiskowy

Automat Spawalniczy do uchwytów czołowych amortyzatorów (Loop Welder)

Zgrzewarka Collar Welder

Maszyna do wykonywania wgniecenia rur MWW 260 (Tyre Dent)

Automat spawalniczy dwustanowiskowy ASDo

Maszyna do mycia i czyszczenia rur MCR

Jednostanowiskowy automat do spawania liniowego ASL (Hook Welder)

Automat Spawalniczy Jednostanowiskowy ASJ

Automat spawalniczy do układów wydechowych COA