Overhaul of industrial machinery and equipment is our main activity. From the very outset of our business, we have been carrying out overhauls on various types of machinery.

We specialise in the complete overhaul and ongoing repair of medium-sized machinery (max. 15 t), particularly machine tools, press, and specialty equipment, primarily for the automotive and electrical machinery industries.

The overhaul/repair process for each piece of machinery or equipment includes:

- Agreement with the client – a process of direct talks and an initial assessment of the technical condition of the machine or equipment, as well as an analysis of the technical specifications of the client,

- Determination of the final scope of work – this stage includes the final arrangements for the scope of repair and modernisation, the preferred commercial components, spare parts and other additional client requirements,

- Preparation of calculations – the final calculation for the repair is carried out on the basis of detailed agreements regarding the scope of work, commercial components to be used, and the safety rating,

- Disassembly and renovation of parts – this stage involves the complete disassembly of the machine or equipment, refurbishment or replacement of parts and components, and painting of the frame and safety guards,

- Reassembly and installation work – new and refurbished parts and assemblies are re-assembled to the restored machine frame. At this stage, new installations and a control system for the machine or equipment are also implemented,

- Commissioning – this stage includes initial and final start-up and testing, combined with trial production and optimisation of the technical parameters attained,

- Pre-acceptance with the client – this stage involves checking the attained parameters of the machine at our premises with the participation of the client's representatives. Acceptance is carried out according to the procedures and requirements of the client,

- Final acceptance – following successful completion of the initial acceptance, the machine or equipment is sent to the client. After installation and connection at the client’s premises, acceptance is carried out again.

Completion of overhaul/repair works - after the client confirms that the parameters attained by the machine or equipment comply with the requirements set out in the specification, the overhaul/repair process is complete. The client receives updated DTR documentation for the machine, diagrams of new installations and the EU declaration of conformity.

The experienced and dedicated staff of Apena-Remont

guarantee that the work carried out is of a high quality and meets all Polish and European requirements.

Our activities, level of technical expertise and continuous improvement of qualifications ensure the satisfaction of our clients.

Pionowa zamykarka puszek katalizatorów

Prasa hydrauliczna PR12

Pozioma zamykarka puszek katalizatorów

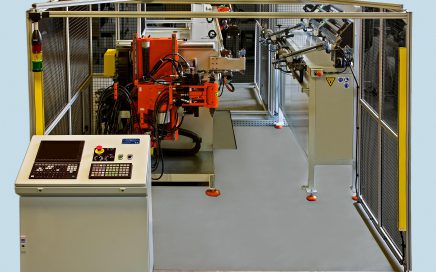

Automat spawalniczy do układów wydechowych COA

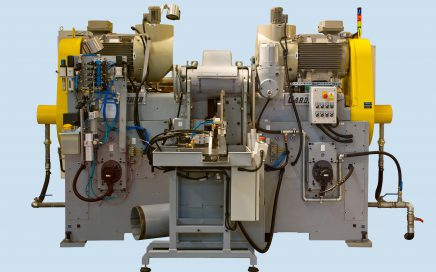

Szlifierka dwutarczowa SDG-5 do szlifowania pierścieni łożysk

Maszyna do testowania amortyzatorów

Body Maker – maszyna do produkcji korpusów katalizatorów

Automat tokarski ATS

Maszyna do podawania karmy Big Bag

Linia do produkcji beczek stożkowych

Wykrawarka Sand

Stanowisko do testowania przewodów Live Tester

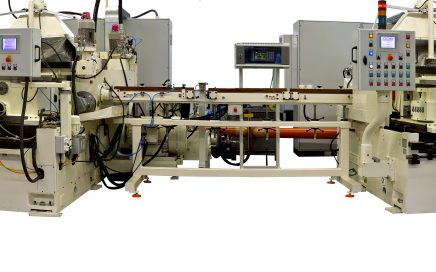

Linia do szlifowania tłoczysk ze szlifierkami Estarta

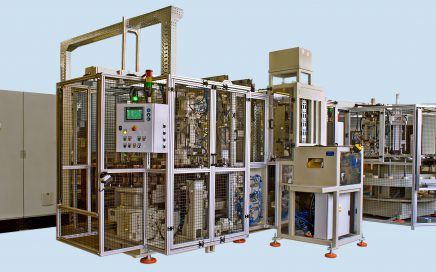

Linia do automatycznego montażu amortyzatorów

Maszyna do zamykania korpusów amortyzatorów

Giętarka Crippa

Szlifierka bezkłowa Cincinnati 3-500 z układem podawania i odbioru tłoczysk

Tokarka TUR 50

Prasa hydrauliczna do wykonywania detali z gumy REP

Szlifierka bezkłowa Cincinnati 340-20

Maszyna do przewężania rur Svager

RUTIL

Notching machine

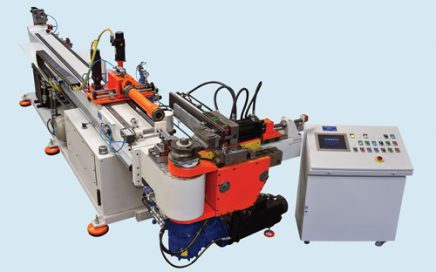

Giętarka rur YLM

Giętarka Leonard

Gildemaister

Szlifierka bezkłowa – ESTARTA 327

Elektryczna giętarka typu Arena

Wielowrzecionowy automat tokarski NB61

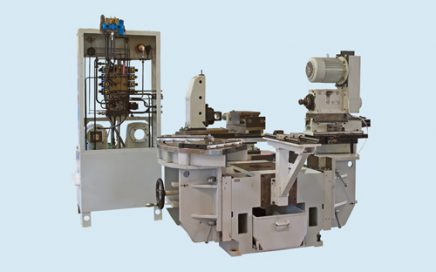

Frezarka wielostanowiskowa FV11

Dogładzarka Supfina SM 464

Giętarka Lang